ICS-2200T Industrial 2-Port RS232/RS422/RS485 Serial Device Server

Cost-effective Solution for RS232/422/485 Serial-to-Industrial Ethernet Application

The Planet ICS-2200T Serial Device Server is designed to convert RS232, RS422 or RS485 serial communication to Industrial Fast Ethernet networking to extend the network distance efficiently and economically. There are two 10/100BASE-TX RJ45 ports available in the ICS-2200T for your network needs. The ICS-2200T is a time-saving and cost-effective solution for users and system integrators to quickly transform their serial devices into the Ethernet network with no need of replacing the existing serial devices and software systems.

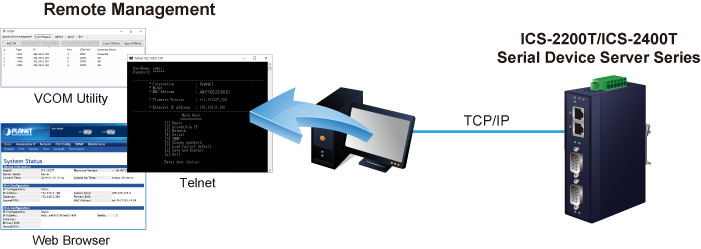

Remote Management

As the ICS-2200T provides an easy serial-to-Ethernet connectivity and connection to a TCP/IP network, the remote network system can thus be managed efficiently via its Web, telnet and VCOM management interfaces. It supports both application and serial operation modes for alarm or IP address connection, which saves the network administrator’s time in detecting and locating network problems without visual inspection of the cabling and devices. Multiple connection options are available for large networking environment.

Stable Performance under Difficult Environments

The ICS-2200T provides a high level of immunity against electromagnetic interference and heavy electrical surges which are usually found on plant floors or in curbside traffic control cabinets. Its operating temperature ranging from -40 to 75 degrees C allows the ICS-2200T to be placed in almost any difficult environment.

The ICS-2200T, equipped with compact IP40 standard metal case, allows either DIN-rail or wall mounting for efficient use of cabinet space. The ICS-2200T also provides an integrated power supply source with a wide range of voltages (12 to 48V DC) ideally suitable for worldwide operation with high availability applications requiring dual or backup power inputs.

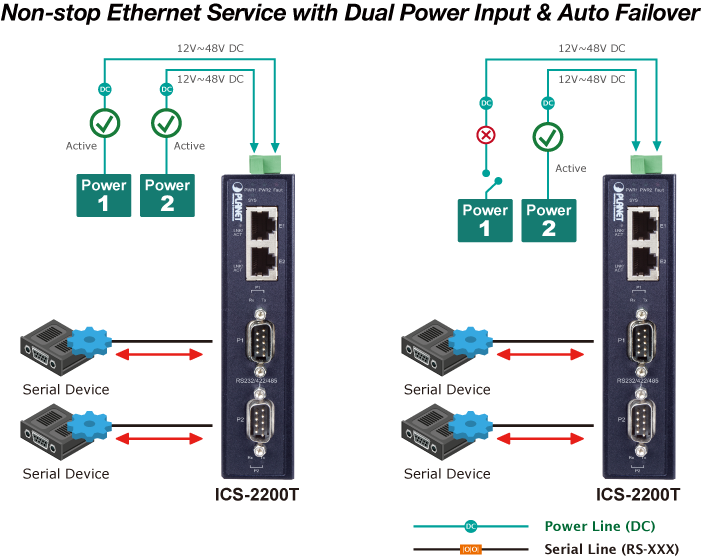

Dual Power Input for High Availability Network System

The ICS-2200T features a strong dual power input system with wide-ranging voltages (12V~48V DC) incorporated into customer’s automation network to enhance system reliability and uptime. In the example below, when Power Supply 1 fails to work, the hardware failover function will be activated automatically to keep powering the ICS-2200T via Power Supply 2 without any break of operation.

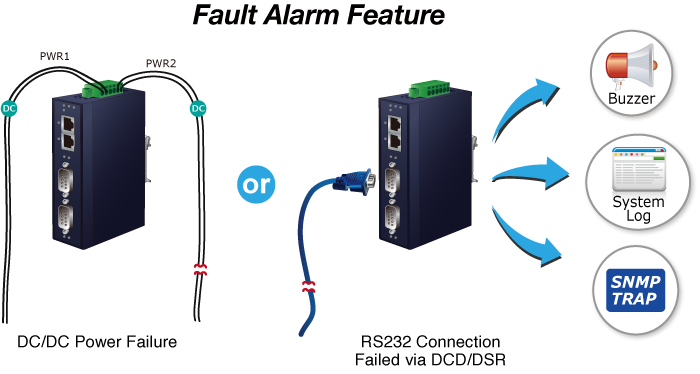

Effective Alarm Alert for Better Protection

The ICS-2200T comes with a Fault Alarm feature which can alert the users when there is something wrong with the Serial Device Server. With this ideal feature, the users would not have to waste time finding where the problem is. It will help to save time and human resource. The ICS-2200T provides event alert function to help to diagnose the abnormal device owing to whether or not there is a break of the network connection, or the rebooting response.

Serial Interface

- Two DB9 interfaces support RS232, 2-wire RS485, 4-wire RS485 and RS422 operation

- Asynchronous serial data rates up to 921600bps

- Data mode including VCOM, RFC2217, TCP Server, TCP Client, UDP, Remote Pair and Serial Telnet modes

Ethernet Interface

- 2-port 10/100BASE-TX RJ45 interface with auto MDI/MDI-X function

- Ethernet ports support Ethernet switch or cascading operation for easy wiring

Management

- IPv4 and IPv6 dual stack management

- Remote Management Interfaces

- IP-based Web management

- Telnet console management

- Windows-based VCOM utility supports searching, monitoring and configuration setting

- IP NTP (Network Time Protocol) and DNS management

- Standard TCP/IP interface and versatile operation modes

- Software Protocol supports ARP, ICMP, TCP/IP, UDP, HTTP server, DHCP client, Telnet server/client

- Serial Operation mode selected via management interface

- Pair Connection mode for connecting two serial devices over a network

- Allows a max. of 4 hosts to be accessed as TCP client mode

- Firmware upgrade via HTTP protocol

- Accessible IP security control to prevent illegal users

- Event notification

- Remote Syslog server

- SNMP trap

- Built-in buzzer

- Relay output alarm

- DHCP client for IP address assignment

- PLANET Smart Discovery utility automatically finds the client devices on the network

Industrial Case and Installation

- IP30 metal case

- DIN-rail and wall-mount designs

- Redundant power design

- 12 to 48V DC, redundant power with polarity reverse protect function

- Supports 6000 VDC Ethernet ESD protection

- -40 to +75 degrees C operating temperature

- Free fall, shock-proof and vibration-proof for industries

- Supports extensive LED indicators for network diagnosis

- Reset button for reset to factory default

| Pin | RS232 | RS422 RS485-4W | RS485-2W |

| 1 | DCD | TxD+ | -- |

| 2 | RxD | TxD- | -- |

| 3 | TxD | RxD- | Data- |

| 4 | DTR | RxD+ | Data+ |

| 5 | GND | GND | GND |

| 6 | DSR | -- | -- |

| 7 | RTS | -- | -- |

| 8 | CTS | -- | -- |

| 9 | -- | -- | -- |

Windows Base Only:

IEEE 802.3 10BASE-T

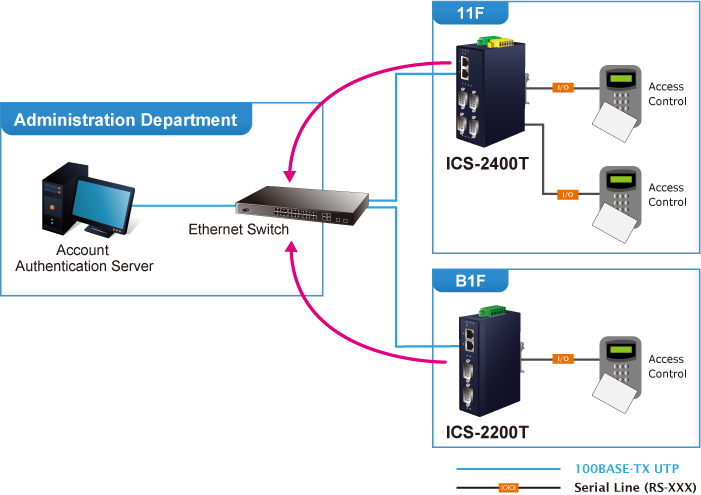

Access Control System – Traditional System Application

Most of the enterprises and government use access control plate and Mifare or RFID to authorize entrance identity. Traditionally, the access control machines use RS232 or RS485 serial interface with their cables connecting to login server. By applying the ICS-2400T, the access control machine is able to extend the network over longer distances via Ethernet interfaces. In addition, the ICS-2200T can be linked to an xDSL router to get the internet access capability so that the access control can be set and monitored over the internet.

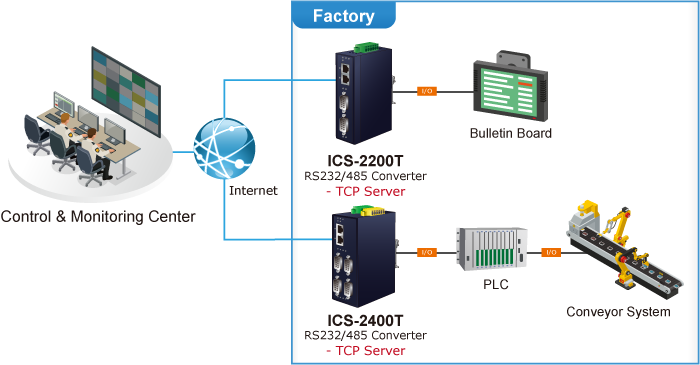

Process Control

To monitor, configure and manage the robotic conveyer including other production machines, PLC (Programmable Logical Control) is required to drive the above manufacturing process. The ICS-2200T can be set to the TCP Server mode and connected to the PLC. Thus, the administrator can configure and set command settings through Fast Ethernet intranet to remotely control the PLC, without having to stand by the I/O machine.

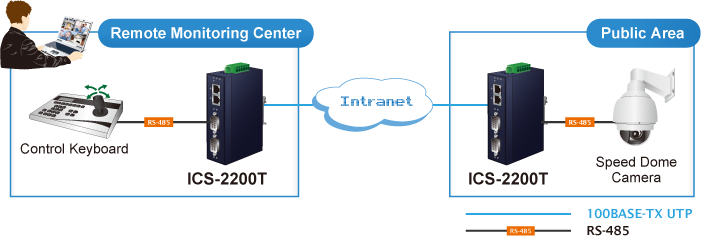

Surveillance Motion Control – Pair Connection Mode

Using pair connection mode via the fibre optical patch cord, the ICS-2200T can extend the distance of the deployed devices via RS232, RS422 and RS485 interfaces, making the remote management of these devices from the monitoring center easier and efficient.

-550x550.jpg)

%20jpg-550x550.jpg)

-80x80.jpg)

%20jpg-80x80.jpg)